Edge Lighting has introduced in-house 3D printing, further strengthening our flexibility to design and produce bespoke components for unique project challenges.

Our first use of this capability was for Waitrose Newbury. While developing new lighting concepts, we encountered a practical challenge: a pendant luminaire needed to hang neatly from two suspension points in a Y-shaped layout.

Existing Y-adapters on the market were either too bulky or lacked the safety and fit we needed. Rather than compromise, we developed a custom solution, our first 3D-printed component.

The first quick sketch exploring the Y-shape angle, clamp points, and internal spacing.

FROM SKETCH TO CAD

The design began as a simple pencil sketch on a post-it note, capturing the concept and rough angles.

We quickly moved into CAD modelling, testing early concepts with steeper angles, and initially considering bolt-on fastening points to hold the two halves together.

An early CAD concept with a steeper angle and bolt-on fastening points for connecting the two halves.

REFINING THE DESIGN

As the concept evolved, we adjusted the angle for a cleaner profile and replaced the early bolt-on fasteners with an interlocking joint that securely connects the two halves.

A key feature of the final design was the inclusion of three safety measures:

- Two external black cable-retention clamps at the top to hold the halves firmly together.

- A third clamp integrated into the interior of the Y adaptor component securing it to the pendant.

- A concealed internal cable tie providing an extra safeguard against cable movement.

The final AutoCAD cross-section showing the internal channel, clamp supports, and interlocking halves.

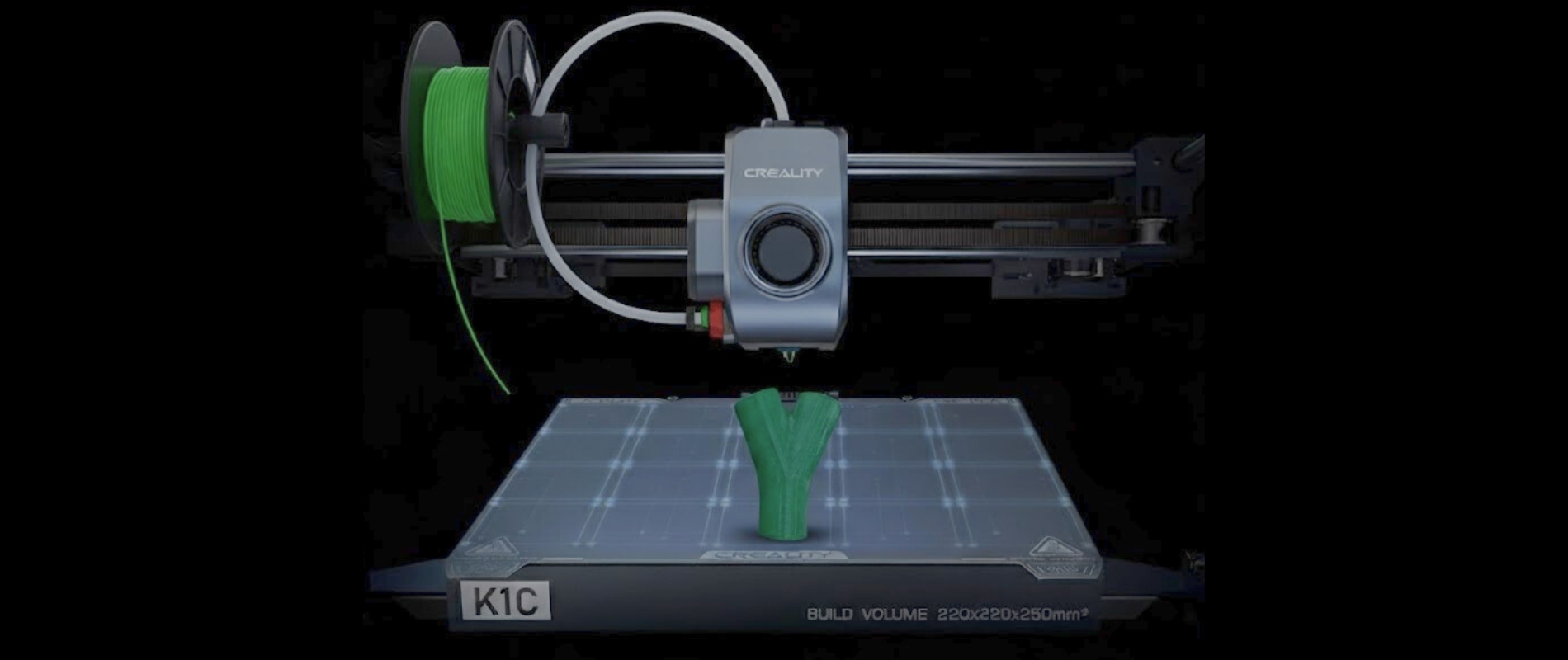

PROTOTYPING IN-HOUSE

Having 3D printing on site meant we could rapidly prototype, test, and refine the design to validate the fit and safety features before installation.

One of the first 3D-printed prototypes: the two halves shown apart to reveal the internal profile.

Prototyping gave us the freedom to fine-tune details such as the angle and clamp depth without delaying the wider Waitrose programme.

The finished Y-Adapter combined a clean, discreet aesthetic with secure functionality, ensuring the pendant luminaire could be installed neatly and safely in a Y-shaped layout.

The finished design, ready for production and installation.

The finished component, installed at Waitrose Newbury.

LOOKING AHEAD

This project demonstrates the value of our in-house 3D printing capability. Being able to progress from sketch to prototype within a single day proved instrumental in solving a specific installation challenge without compromising on safety or design.

With this approach now integrated into our workflow, we can respond to bespoke requirements more efficiently, cut down on lead times, and gain greater flexibility to fine-tune solutions for future projects.